Cooling installation

Voets & Donkers has its roots in cooling technology. We have been active in this sector with our family business since 1953. Over the years, the projects have become bigger and the cooling installations have become more complex.

We work for both large and small customers, nationally and internationally. Whether it concerns a standard refrigeration unit for a cold store or freezer cell or an industrial cascade cooling installation, at Voets & Donkers we have the knowledge and experience in-house to produce a cooling installation that exactly meets your wishes and technical conditions. Indirect cooling, pumping systems or direct expansion with natural refrigerants: these are just a few of the many examples. We offer a wide range of possibilities and supply standard products as well as fully customised complex projects. Many of our regular customers have found a partner in us for all their refrigeration needs.

Reliability and innovation

As a company, we are always innovating in industrial cooling technology. New refrigerants and new techniques are being explored and where possible and relevant, these are deployed immediately. This way we are and always will be up-to-date in our services.

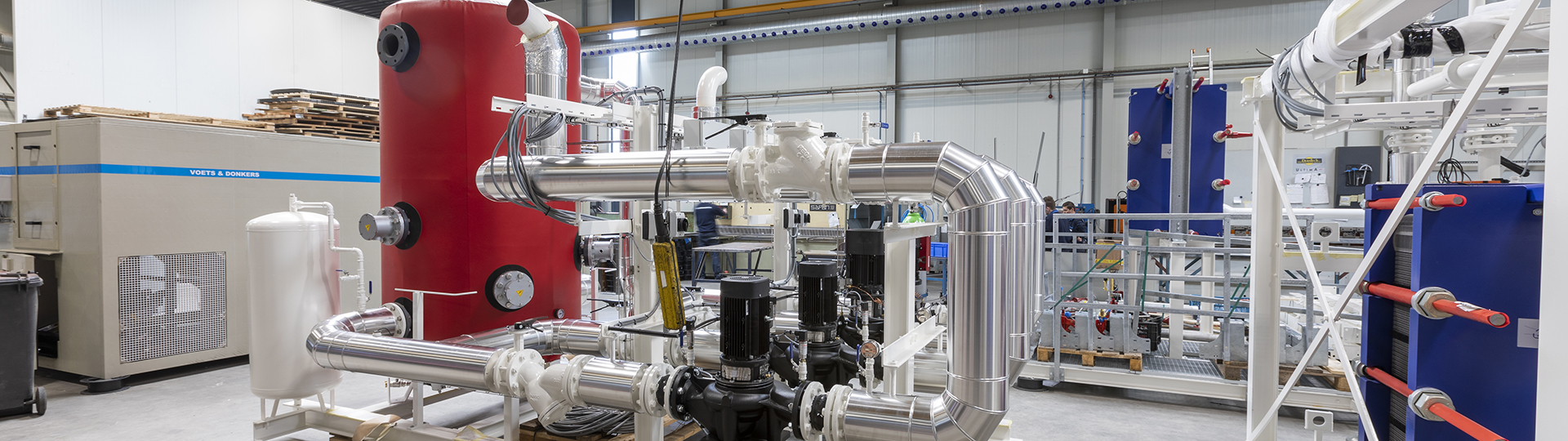

Reliability and quality are paramount in everything we do. Cooling machines often run many hours of operation and are often part of your essential business process(es). We will therefore give the reliability of your installation the necessary care and attention. The level of finish of our cooling installations is also high. For example, we work with stainless steel piping almost as standard.

Modular work

Because we carry out the engineering of our projects in-house, it is possible to work in a modular way. This means that we build the cooling machine in our own workshop as much as possible. This is then checked for leaks, wired and already partially insulated before it is transported to the project location. This not only works pleasantly, but above all very efficiently.

Heat recovery is becoming increasingly important in today’s cooling technology. At Voets & Donkers we stand for smart, sustainable designs. This enables us to recover all the heat generated during the necessary cooling for useful reuse. At times when heat is needed, but cooling is not, our more advanced installations can even switch to heat pump operation. Read more about sustainability and heat recovery here.

Sectors at Cooling installation

Cheese maturation

As a cheese producer, you know better than anyone that there are countless types of cheese and that each cheese has its own properties. The air conditions in your warehouse play a major role in this; after all, they determine to a large extent how your cheese matures and (therefore) tastes. Voets & Donkers is a specialist in creating exactly those conditions that optimise cheese maturation and give your cheese its own characteristic and perfect taste.

Fresh produce

Optimum taste, quality and shelf life are of great importance in the fresh produce sector. At Voets & Donkers we have the knowledge, experience and expertise to offer added value as a refrigeration company. We have many customers in the fresh produce sector: from small-scale farms to large fresh centres. With cold stores and freezers in all shapes and sizes, we offer a wide range of possibilities. Whether it concerns a cold store on the farm, a vegetable-processing factory or a large (refrigerated) warehouse… we are at your service!

Pharmaceuticals

The conditions under which medicines are produced, processed and stored are of great importance for their quality. As a pharmaceutical manufacturer or wholesaler, you need a reliable partner in this field. At Voets & Donkers we have extensive experience in creating exactly the right air conditions for the storage of medication.

Warehousing

Different wishes and requirements apply to each distribution centre or warehouse in terms of temperature and (ultra-clean) air conditions. With our knowledge and experience in industrial refrigeration technology and air treatment installations, we can optimise the quality and shelf life of the stored products.

Food products

As a producer or processor of food, you know that hygiene is essential. The air quality must be optimal so that no contamination enters the packaging or the product during processing or packing. At Voets & Donkers, we specialise in creating an ultra-clean air quality for the production, processing and storage of food products.

Sustainability

Sustainability is very important in our society today. We ‘have to’ get rid of the gas, and we also try to limit our use of electricity as much as possible. At Voets & Donkers, our installations contribute to sustainability in three ways: we use natural refrigerants, we develop energy-efficient installations and we make heat recovery possible.